Cobra is breathtaking thumbhole precision stock specifically designed for precision shooters and long-range hunters who prefer the unique ergonomics the style provides. WOOX’ approach to creating its first thumbhole stock takes advantage of the unique comfort and control characteristics that can only be had with genuine wood. When combined with WOOX’s modular chassis, the result is nothing short of amazing: increased comfort, a steady shooting platform, and consistent shot-to-shot sub-MOA accuracy.

Proudly made in Italy and USA.

| Features | Detail |

|---|---|

| Installation | Drop-in. Does not require pillars or extra bedding. |

| Grip | Ambidextrous |

| Chassis | AA 7075 aircraft-grade aluminum, hard anodized. |

| Wood Material - Colors | American Walnut - Walnut Laminated wood - Tiger Wood |

| Specification | Value |

|---|---|

| LOP | 14"

Adjustable with spacers (sold separately) |

| Cheek Riser Height at Min - Max | 5.5" - 6" |

| Recoil Pad | Fixed

Vertical Adjustment: None Horizontal Adjustment: None Shape: Standard. |

| Total Weight * | 3.8 - 4.3 lbs |

| Forend Weight * | 0.6 lbs |

| Internal Chassis Weight * | 1.5 - 2 lbs |

| Buttstock Weight * | 1.7 lbs |

* The weight of our stocks can vary slightly due to natural variations in the density of the wood used and differences between compatible rifle models.

| Rifle Model | Max Floating Barrel |

|---|---|

| Remington 700 | 1.17” |

| Savage LA | 1.15” |

| Sauer 100 | 1.10” |

| Tikka, Ruger, Howa, Weatherby, CZ, Savage SA | 0.95” |

That's a question we get a lot, and we've made it easy to find out.

To help you find your perfect match, consult our detailed compatibility list, specifically curated to eliminate guesswork and ensure a seamless fit.

Need more guidance? Contact us!

| Spec | Description |

|---|---|

| Installation | Drop-in. Does not require pillars or extra bedding. No gunsmithing required. |

| Grip | Ambidextrous |

| Chassis | AA 7075 aircraft-grade aluminum, hard anodized. |

| Stocks | American Walnut, Laminated |

| LOP | 13.5” - 14” (spacers included) |

| OAL | 32” |

| Weight | 3.5 - 4 pounds |

| Max Floating Barrel | Remington 700 models: 1.17” Savage LA models: 1.15” Sauer 100 models: 1.10” Tikka, Ruger, Howa, Weatherby, CZ, Savage SA models: 0.95” |

| Colors | Walnut, Tiger Wood |

“Some things aren’t meant to be rushed. Like respect.”

At WOOX, we don’t cut corners to cut costs. We craft each piece the way our grandfathers built their names—with time, care, and pride.

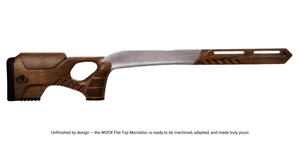

The WOOX Flat Top Monobloc is precision CNC-machined from a single block of 6082 aluminum, ensuring maximum strength and accuracy.

Delivered in an unfinished state, it’s designed for full customization based on the shooter’s or manufacturer’s specific needs.

The monobloc is supplied without any surface treatment to allow complete freedom in both milling and finishing.

It’s built for versatility—if your platform is not compatible with current WOOX models, a custom-fit version can be produced.

Disassembly, milling, and reassembly must be performed exclusively by a qualified gunsmith.

After machining, the monobloc can be finished to your preferred specifications.

Following a light sandblasting, it may be treated with either hard anodizing or a Cerakote coating.

In both cases, we recommend relying on trusted professionals to ensure optimal results.

| Specification | Details |

|---|---|

| Material | 6082 Aluminum, CNC machined |

| Internal dimension | A = 9.72 In. | 24,70 Cm

B = 1.25 In. | 3,17 Cm |

| Weight * | 2.88 lbs. | 1,31 Kg |

* Weight related to the solid monobloc, without inletting or additional custom milling, without finishing treatments.

The image shows the WOOX Flat Top Monobloc in its raw, unfinished state, exactly as it is delivered.

Before it can be mounted on a rifle, the monobloc must be milled, fitted, and finished by a qualified gunsmith, according to the specific platform and user preferences.

• Disassembly and reassembly of the monobloc must be carried out by a qualified gunsmith*,following the WOOX Flat Top Monobloc Disassembly/Assembly instructions reported below.

• All milling operations must be performed by a skilled gunsmith with machining aluminum experience*, in accordance with the technical specifications of the customer’s firearm.

• Once machining is complete, the monobloc can be finished as desired. Following light sandblasting,the monobloc can be treated with hard anodizing or Cerakote coating, based on the customer's preferences. Always refer to qualified professionals*.

* Incorrect operations (milling, machining, finishing, disassembly & reassembly) will void the warranty

While we guarantee the quality of the materials and original workmanship, the warranty

does not cover any modifications made after delivery.

What the warranty covers:

• The structural integrity of wood and aluminum parts as delivered.

• Manufacturing defects identified prior to any work performed by third parties.

What the warranty does not cover:

• Any damage or malfunction caused by milling, anodizing, or reassembly.

• Modifications performed by gunsmiths or third parties.

• Wear, misalignment, or failure due to improper tightening or installation.

WHEN DISASSEMBLING/ASSEMBLING THE MONOBLOC, THE FOLLOWING STEPS MUST BE TAKEN BY A QUALIFIED GUNSMITH:

DISASSEMBLY

1. Using a T25 bit, remove the screw at the front tip of the forend.

2. Using a T20 bit, remove the nine (9) M-LOK screws from the 3, 6, & 9 o’clock position of the forend.

3. Remove the forend by sliding forward and away from the monobloc.

4. Using a T25 bit, remove the two (2) screws from either side of the spine.

NOTE: The spine screws will be shipped without loctite for easy removal. When reinstalling after inletting, ensure to add loctite to these screws prior to reinstallation of the forend.

ASSEMBLY

1. Insert spine into front end of monobloc.

2. Unsing a T25 bit and red Loctite, reinstall the screws on either side of the spine and torque to 55 in/lbs.

3. Reinstall the forend onto the spine and slide towards monobloc until secure.

4. Using a T20 bit, reinstall the nine (9) M-LOK screws and hand tighten.

5. Using a T25 bit, reinstall the screw into the front tip of the forend.